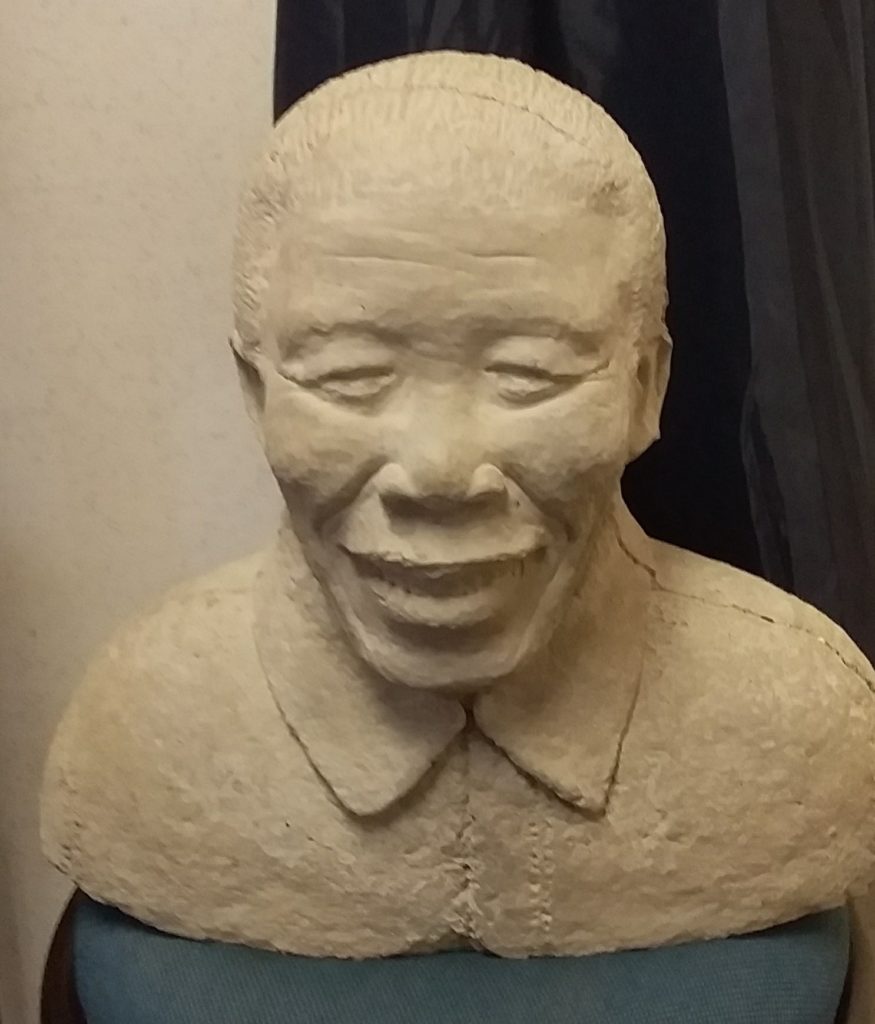

He made and took his waste paper sculptures to the National University of Lesotho (NUL) Innovation Hub. Then he came back with exact copies of the same sculptures but now made of plastic and cement! They had been copied and reproduced to the smallest detail! Mr Korone Moea is a self-taught fine sculptor who shapes with paper. However, once he has produced a good product and it has been sold, he faces a reality many sculptors have to face. He will never produce exactly the same product again!Never!(Drop him an sms in these digits: +266 59417178).Plus, the hard work in having to produce the same thing from scratch every time he gets a new customer is maddening!That was, until he met some chaps from the NUL Innovation Hub. “I was in an expo organised, I think by BEDCO, at the Pioneer Mall, when I was approached by these folks from the Hub,” Moea said.“They were impressed by my art and one of them asked me an intriguing question. He said, “what happens to this fine art once someone has bought it? Can you produce for me, exactly the same item again?” I said No!”“The guy looked me in the eye and said, “we think we can provide a little bit’a help at the NUL, let’s try.””Moea said he was asked to produce a number of art items, small and big, using his waste paper, “I still remember one was a huge lion sculpture, another was Nelson Mandela sculpture and another was a very small sculpture of Moshoeshoe I.” He then journeyed to the NUL to see if it was possible to reproduce such things at all. “I left my model sculptures there and waited patiently,” –until he was consulted. When he arrived, he could not believe his eyes. The tiny Moshoeshoe I sculpture he made out of paper had been transformed into a very hard plastic sculpture! How? He didn’t know. The Mandela and the lion statues, previously made out of paper, had been moulded into cement statues. The details were exactly the same! Only the material used had changed. He was stunned!But how did they do it? So we approached those chaps at the NUL Innovation Hub and they were willing to reveal a not-so-difficult-to-understand science behind the whole thing. It all starts with sand, they said. Yes, sand from sand stone. Sand is made of silicon and oxygen (quartz). When it is heated under very high temperatures, “the oxygen and silicon separate,” the scientists explained, “leaving silicon element to use as one wishes.”That silicon element is used to make Silicone Rubber. Well it is not a rubber (how can a rubber be made from stone?). It is just rubberlike. And it is not even silicone rubber (its true name is polydimethylsiloxane). The NUL scientists use it after it has been made into liquid polydimethylsiloxane in a rather complicated process upstream.“In our laboratories, we do what we call polymerisation to turn this liquid material into a hard but rubberlike material,” the scientists said. During the process, the soft, flexible, rubber-like material, forms around a model to be reproduced, creating a mold that can be reused many times. In the case of large sculptures—like Mandela and lion ones—thin layers of “silicone rubber” are used in conjunction with a strong backbone of fibreglass. So the self-taught sculptor, Mr Moea, will soon benefit from this “simple” technology to ensure he reproduces and sells as many of his sculptures as possible. He said he has always been sculpturing since he was young, using clay. “I was never really good at this work but I think I developed love for it until I could master it,” he said.He was once living in Bloemfoentein when he saw one gifted soul making ash trays out of waste paper and water. Back home, he tried his lack by sculpting humans and, to his surprise, his neighbours started buying. Later, his art met science at the NUL Innovation Hub. Hopefully, good things are coming out of it all.